Top Tips for Choosing the Best MIG Welder in 2025 for Your Projects

When it comes to selecting the best MIG welder for your projects in 2025, it's crucial to consider various factors that can significantly impact your welding experience and results. As industry expert Mark Thornton, a seasoned welding instructor, states, "Investing in the right MIG welder not only improves your skill but also ensures that your projects are executed with precision and efficiency." This highlights the importance of making an informed decision when you decide to buy MIG welder.

Many beginners and even experienced welders often find themselves overwhelmed by the numerous options available in the market. From understanding the different specifications to determining the right features for your specific needs, the process can be daunting. However, with the right knowledge and guidance, choosing a suitable MIG welder can be a smooth experience. Whether you are working on a DIY project at home or tackling more complex industrial tasks, knowing what to look for can save you time and money in the long run.

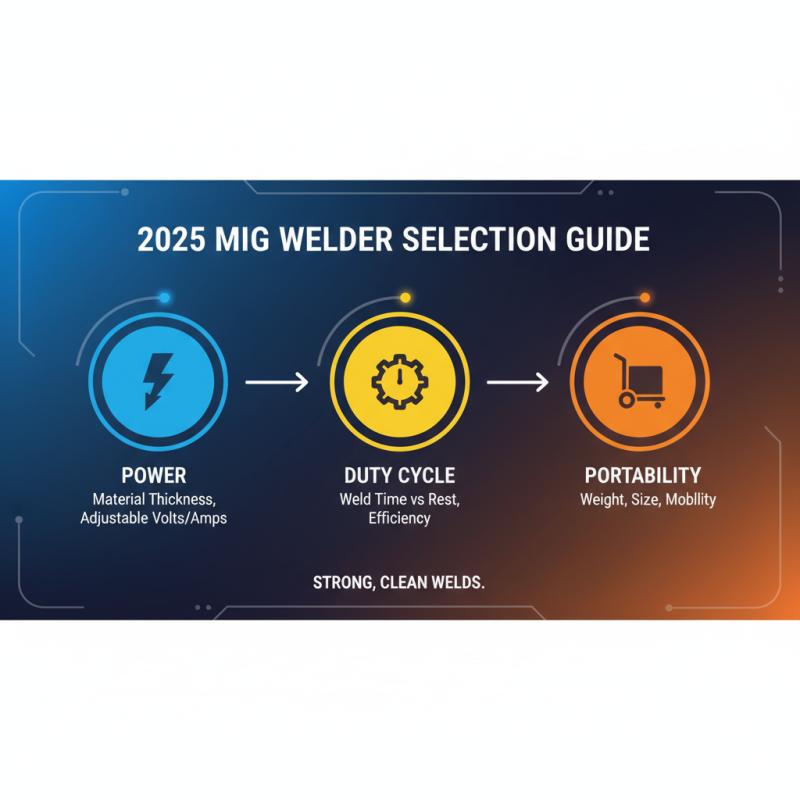

In this article, we will offer top tips to guide you through the process of selecting the ideal MIG welder for your requirements. By focusing on key features such as power output, duty cycle, portability, and user-friendliness, you will be well-equipped to make a purchase that meets your welding aspirations. As you prepare to buy MIG welder, keep these insights in mind to enhance your welding efficiency and output quality.

Key Factors to Consider When Choosing a MIG Welder in 2025

When selecting a MIG welder in 2025, it's essential to evaluate key factors that influence both performance and usability. One of the primary considerations is the power output, measured in amperage, which determines the welder's ability to handle various metal thicknesses and types. A MIG welder with a higher amperage range provides greater versatility, making it suitable for both light-duty tasks and more demanding projects. Additionally, consider the duty cycle, which indicates how long the welder can operate before needing a cooldown period. A longer duty cycle is advantageous for extended welding sessions, particularly in professional environments.

Another critical factor to consider is the welder's weight and portability. For projects that require moving around the workspace or traveling to different job sites, a lightweight and compact model will enhance mobility without sacrificing functionality. Furthermore, look for features such as ease of setup, adjustable settings, and compatibility with various wire sizes and types. A user-friendly interface can significantly impact the welding experience, especially for beginners or hobbyists. Lastly, assessing safety features, such as thermal overload protection and safety shutoff, can provide added peace of mind while working with high-power equipment.

Top Tips for Choosing the Best MIG Welder in 2025 for Your Projects

| Key Factor | Description | Importance |

|---|---|---|

| Power Supply | Voltage and amperage capacity necessary to handle various materials and thicknesses. | High |

| Welding Thickness Capability | Ability to weld different thicknesses of materials effectively. | Medium |

| Ease of Use | User-friendly controls and setup for both beginners and experienced welders. | High |

| Portability | Weight and design that allow for easy transportation and use at various sites. | Medium |

| Duty Cycle | Time a welder can operate continuously before it needs cooling. | High |

| Material Compatibility | Ability to weld different materials, such as steel, aluminum, and stainless steel. | High |

| Additional Features | Features like digital displays, automatic settings, and gas flow control for enhanced usability. | Medium |

Understanding Different MIG Welder Types and Their Applications

When choosing a MIG welder, it's essential to understand the different types available and their respective applications to make an informed decision tailored to your projects. MIG welders can generally be categorized into two main types: gas-shielded and self-shielded.

Gas-shielded MIG welders use an inert gas, typically argon or a mixture of gases, to protect the molten weld from contamination. This method is particularly effective for welding thin materials and is favored in professional settings due to the clean finish it offers.

On the other hand, self-shielded MIG welders eliminate the need for external gas by using a flux-cored wire that generates its own shielding gas during the welding process. This type is considerably more portable and is ideal for outdoor projects where wind might disperse shielding gas. Self-shielded welders are often used in construction or repair work, where durability and ease of use are critical. Understanding these distinctions helps you select the right welder based on the materials you'll be working with and the specific conditions of your projects.

Regardless of the type you choose, ensure it aligns with your welding needs, skill level, and the environment in which you'll be working.

Evaluating MIG Welder Features: Power, Duty Cycle, and Portability

When selecting the best MIG welder for your projects in 2025, it's essential to evaluate critical features such as power, duty cycle, and portability. Power is a fundamental aspect, as it determines the welder's ability to handle various materials and thicknesses. A welder with adjustable power settings is advantageous, allowing users to tailor their settings based on specific needs, whether they are working with thin sheet metal or thicker components. It's vital to consider the voltage levels; higher voltage machines can perform more efficiently on thicker materials, contributing to a cleaner and stronger weld.

Duty cycle is another crucial factor that can significantly affect your welding projects. It refers to the amount of time a welder can operate within a specific timeframe before it needs to cool down. A welder with a higher duty cycle is ideal for extensive or continuous work, enabling productivity without frequent interruptions. For hobbyists or those with lighter jobs, a lower duty cycle might suffice, but understanding your workload is essential to make an informed choice.

Portability also plays a significant role, especially for those who work in multiple locations or on-site projects. A lightweight, compact MIG welder can enhance mobility and ease of use. Look for features like roll cages or integrated handles that facilitate transport. Moreover, assessing the power source options, such as dual voltage capability or compatibility with generator power, can further improve the welder's versatility for various job sites. With these features in consideration, you can select a MIG welder that perfectly aligns with your project requirements in 2025.

Assessing Budget Considerations for Your MIG Welder Purchase

When considering the purchase of a MIG welder, budget plays a crucial role in determining the right model for your needs. Before diving into the specifications and features, it's essential to outline how much you’re willing to spend. A thoughtful budget allows you to balance quality and performance while avoiding unnecessary overspending on equipment that may exceed your project requirements. Remember to consider not only the upfront costs but also potential long-term expenses such as consumables, maintenance, and any additional tools you might need.

In addition to the initial cost, keep in mind that MIG welders are available at various price points, often reflecting their capabilities and included features. For hobbyists or those working on small projects, more affordable options may suffice, providing basic functionalities without overcomplicating the process. On the other hand, professionals or users intending to tackle complex projects may find investing in higher-end machines worthwhile, as these often offer better performance, reliability, and advanced features that can streamline their work. Setting clear priorities will help ensure that your purchase aligns with both your immediate budget and future welding ambitions.

Top Brands and Models of MIG Welders to Look for in 2025

When looking for the best MIG welder in 2025, it is essential to focus on top brands and models that provide durability, ease of use, and versatility for various projects. Among the key features to consider are the welder's power output, duty cycle, and weight. A powerful welder will enable you to work with thicker materials, while a high duty cycle ensures that you can weld for extended periods without overheating. Lightweight models are advantageous for portability, allowing for greater flexibility in project locations.

Some of the most reputable models on the market emphasize user-friendly interfaces and advanced technology, such as digital displays and automatic settings that adapt to the welding conditions. These innovations make the welding process smoother and enhance overall performance. Additionally, consider welders that come with adjustable settings to accommodate different wire diameters and gas types, enabling you to tailor your equipment to specific tasks. Researching user reviews and expert opinions can further help you identify the best options that align with your individual welding needs in 2025.

Top MIG Welder Types and Their Popularity in 2025

Related Posts

-

Ultimate Guide to Buy Mig Welder Tips for Beginners and Experts

-

Understanding the Essential Components of MIG Welding Equipment for Beginners

-

How to Choose the Best Cheap Mig Welder for Your Welding Projects

-

2025's Ultimate Guide to the Top 10 Portable Spot Welders for Every DIYer

-

2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

-

Unveiling the Best Spot Welder for Home Projects with Essential Insights and Expert Tips

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request