2025 How to Choose the Right Resistance Spot Welder for Your Needs

In the evolving world of manufacturing and metal fabrication, choosing the right equipment is crucial, especially when it comes to essential tools like a resistance spot welder. According to industry expert Dr. Emily Johnson, "The efficiency and quality of your welds can significantly impact overall production, making it vital to select a welder that aligns with your specific operational needs." As technological advancements continue to shape welding techniques, understanding the features and capabilities of a resistance spot welder can help professionals make informed decisions that enhance productivity and ensure consistent results.

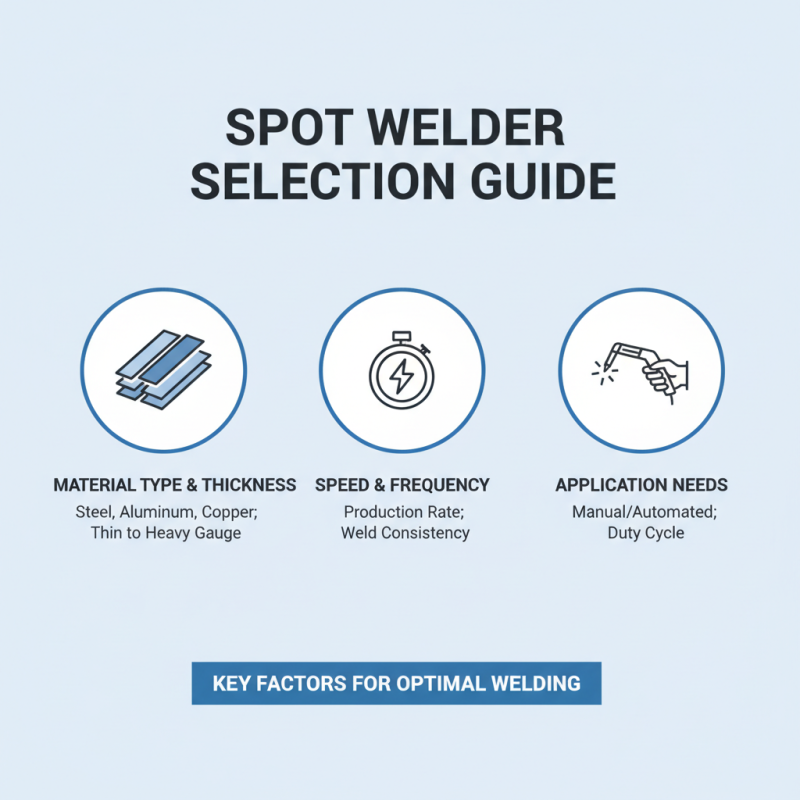

Selecting a resistance spot welder may seem straightforward, but the array of options available can be overwhelming. Factors such as the type of materials being welded, the thickness of those materials, and the anticipated production volume play critical roles in determining the most suitable model. Moreover, with features like adjustable welding parameters and automated systems becoming standard, understanding these specifications is key to leveraging the full potential of a resistance spot welder.

In this guide, we will explore the essential considerations for choosing the right resistance spot welder tailored to your unique requirements. Whether you are a seasoned welding professional or a newcomer to the field, gaining insight into this powerful tool will ultimately lead to improved fabrication quality and efficiency.

Factors to Consider When Choosing a Resistance Spot Welder

When selecting the right resistance spot welder for your needs, there are several critical factors to consider. First, determine the materials you will be working with, as different welders are better suited for specific metals such as steel, aluminum, or copper. The thickness of the material also plays a significant role; some welders are designed for thin sheets while others can handle heavier materials. Additionally, consider the required welding speed and frequency, as these factors influence your productivity and output quality.

Another essential aspect to evaluate is the power output of the welder. This will affect the penetration and strength of the welds you create. Ensure that the machine has adjustable settings to fine-tune the weld according to your material and project requirements. It’s also beneficial to look for features that enhance safety and ease of use, such as built-in cooling systems and ergonomic designs, which can make a significant difference during extended work sessions. Lastly, assess the support and maintenance options available, as these can impact the longevity and reliability of your investment.

Types of Resistance Spot Welders Available in the Market

When selecting a resistance spot welder, understanding the different types available in the market is crucial for making an informed decision that meets your specific needs. The most common types include portable welders, stationary welders, and automated or robotic welders. Portable welders are ideal for smaller projects or on-site tasks where space and mobility are essential. They typically feature a lightweight design, making them easy to transport without sacrificing welding quality.

Stationary welders, on the other hand, are best suited for larger operations or industrial settings. These machines are designed for high-volume production and offer greater stability and power. They usually come with advanced controls for precision and consistency, making them perfect for critical applications where weld quality is paramount.

Automated or robotic welders are increasingly popular in modern manufacturing. These sophisticated systems utilize robotics to perform repetitive welding tasks with extreme precision, reducing human error and improving efficiency in production lines.

Choosing the right type of resistance spot welder involves understanding your specific requirements, including the materials you work with, the volume of production, and the need for portability versus stability. Each type has its strengths and is suited to different applications, so it’s essential to assess your needs thoroughly before making a choice.

Key Specifications and Features to Look For

When choosing the right resistance spot welder for your needs, several key specifications and features deserve your attention. First, consider the welder’s power output, typically measured in kilowatts. A higher power output can result in improved welding speed and efficiency, especially for thicker materials. Check the voltage specifications as well, since a welder that operates on standard voltage will often be more convenient for home or shop use.

Another critical feature to evaluate is the control options available. Look for welders with adjustable timer settings and electrode pressure controls, which enable you to customize the welding process to match the thickness and type of metals you plan to work with. Additionally, automatic or programmable settings can enhance usability, allowing for consistent results across multiple welds. Finally, inspect the overall build quality and design of the machine, ensuring it is durable and ergonomically designed for ease of use during extended welding sessions.

Understanding Your Welding Needs and Applications

When choosing a resistance spot welder, it's crucial to first understand your specific welding needs and applications. Different projects may require varying power levels, electrode types, and welding techniques. For instance, if you're working on automotive repairs or fabrication projects that involve thin metal sheets, you'll need a welder that can deliver precision without excessive heat, which can warp the material. Conversely, thicker components like structural parts may necessitate a more robust machine capable of generating higher levels of power.

Tips: Assess the materials you frequently work with. Aluminum and stainless steel require different settings and techniques. Having an idea of the thickness and types of metals will direct you toward the right welder functionality and features that fit your application.

Also, think about the welding environment. If you'll be using the welder in a confined space or on-site, portability may be a key factor in your decision. Ensure that the machine is not only compact but also easy to transport without compromising performance.

Tips: Look for ergonomic designs that facilitate ease of use and movement. User-friendly controls can make a significant difference in productivity, particularly if you're tackling multiple projects throughout the day. A welder that fits comfortably in your workspace will enhance your overall efficiency and effectiveness.

Budget Considerations for Purchasing a Resistance Spot Welder

When considering the purchase of a resistance spot welder, budget is often the most significant factor influencing your decision. The price range for these machines can vary widely based on their capabilities, size, and features. It's essential to establish a clear budget before diving into your options. Assess your intended applications—whether for hobbyist projects, small-scale manufacturing, or heavy industrial use—to determine the level of investment required.

A basic model might suffice for lighter tasks, while more sophisticated projects will necessitate a higher-end welder capable of meeting specific technical demands.

Additionally, it's crucial to consider the long-term costs associated with owning a resistance spot welder. While an initial lower-priced option may seem appealing, it may lack durability or required functionalities. On the other hand, investing in a quality machine can lead to lower maintenance and operational costs in the long run. Additionally, always factor in expenses such as replacement parts, accessories, and training if necessary. A well-planned budget that encompasses both the upfront cost and future expenditures will help ensure that you select the right resistance spot welder to meet your needs efficiently and economically.

Related Posts

-

2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

-

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

-

Ultimate Guide to Buy Mig Welder Tips for Beginners and Experts

-

Ultimate Guide to Mobile Welding Techniques for Every DIY Enthusiast

-

Revolutionizing Industrial Manufacturing: The Future of Seam Welding Machines in Modern Applications

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request