Why Choose a Resistance Spot Welder for Your Welding Projects

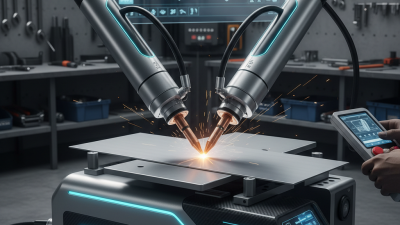

When it comes to welding projects, the choice of equipment can significantly impact the quality and efficiency of the work. Among the various welding tools available, a resistance spot welder stands out for its unique advantages. This method of welding involves applying pressure and an electric current to join two metal surfaces, creating strong, reliable welds with minimal distortion. The versatility and precision of a resistance spot welder make it an ideal choice for a wide range of applications, from automotive manufacturing to metal fabrication.

One of the primary reasons to choose a resistance spot welder is its ability to deliver consistent results. This equipment is designed to ensure that each weld is uniform, which is crucial for maintaining structural integrity in assembled parts. Additionally, the speed at which a resistance spot welder operates allows for high productivity, making it a valuable asset in any workshop. As the demand for efficient and reliable welding solutions continues to grow, understanding the benefits of a resistance spot welder can inform better decision-making for both hobbyists and professionals alike.

Understanding Resistance Spot Welding: Basics and Benefits

Resistance spot welding is a vital technique in the manufacturing industry, recognized for its efficiency and strength in joining materials, particularly metals. This process involves applying pressure and electrical current to metal sheets, creating a weld at the junction points without compromising the surrounding material. According to a report by the International Institute of Welding, resistance spot welding accounts for over 80% of the welds made in automobile assembly, emphasizing its prominence in high-volume production environments.

One of the main benefits of resistance spot welding is its speed and energy efficiency. Industry studies have shown that spot welds can be produced in mere seconds, drastically reducing cycle times in manufacturing. Furthermore, resistance spot welding consumes less energy compared to traditional welding methods—up to 90% less per weld—making it a cost-effective solution. Additionally, the minimal heat-affected zone (HAZ) ensures that the integrity of the materials remains intact, which is crucial for applications requiring high safety standards, such as in automotive and aerospace industries. These advantages demonstrate why resistance spot welding is not just a technique but an essential aspect of modern welding projects.

Resistance Spot Welder Benefits and Applications

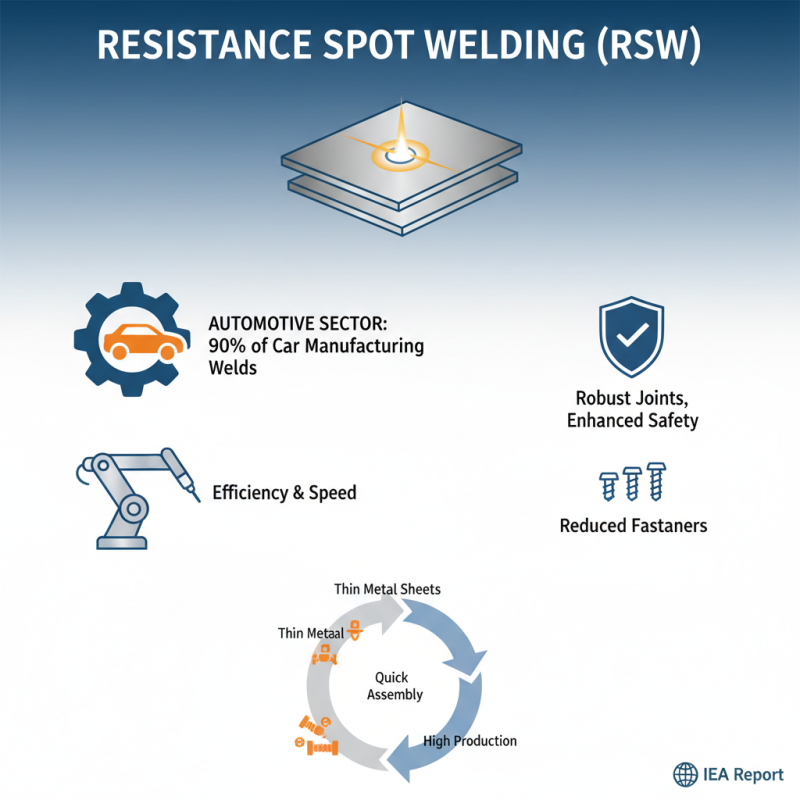

This chart illustrates the various applications of resistance spot welding across different industries, highlighting its significance in the automotive sector, followed by construction, electronics, aerospace, and appliances.

Key Advantages of Using Resistance Spot Welders

Resistance spot welders offer significant advantages for various welding projects, especially in manufacturing and fabrication processes. One of the key benefits is efficiency. These machines provide quick and effective joins between metal pieces, often completing the weld in mere seconds. This rapid process not only speeds up production times but also helps to maintain precision and reduce the heat-affected zone, ensuring minimal distortion of the materials involved.

Additionally, resistance spot welding is highly consistent, making it an ideal choice for repetitive applications. The technology relies on electrical resistance to generate heat at the weld interface, which results in a strong bond without the need for additional filler materials. This method also enhances the overall strength and durability of the joints. The ability to automate resistance spot welding allows for greater reliability in high-volume operations, ensuring that each weld meets the desired quality standards. Overall, these advantages make resistance spot welders a smart investment for those looking to streamline their welding processes while maintaining high-quality results.

Applications of Resistance Spot Welding in Various Industries

Resistance spot welding (RSW) is a pivotal technique widely employed across various industries due to its efficiency and adaptability. One of the most prominent applications is in the automotive sector, where RSW plays a crucial role in assembly lines. According to a report by the International Energy Agency, approximately 90% of all welding in car manufacturing is done using spot welding techniques. This method allows manufacturers to create robust joints between thin metal sheets quickly, significantly enhancing production speed and safety, while reducing the need for additional fasteners and assembly components.

In addition to the automotive sector, resistance spot welding is extensively utilized in the electronics industry. A study published by the Institute of Electrical and Electronics Engineers noted that RSW is ideal for bonding thin wires to circuit boards, ensuring optimal conductivity and minimal heat distortion. The precision and control offered by spot welding technology make it possible to manufacture high-density electronic assemblies that meet the increasing demands for miniaturization and performance. This versatility not only boosts product reliability but also advances the efficiency of electronic manufacturing processes.

Other industries, such as aerospace and construction, have also embraced RSW for its ability to join dissimilar materials and produce lightweight, durable constructions. Recent data from the American Welding Society indicates a growing trend towards the use of resistance welding techniques in fabricating high-strength structures without compromising on weight. This capability is paramount in sectors where performance and safety are critical, thus underscoring the significance of resistance spot welding in modern manufacturing paradigms.

Comparing Resistance Spot Welding to Other Welding Techniques

Resistance spot welding is a popular choice for many welding projects due to its efficiency and effectiveness in joining sheet metal. Compared to traditional welding techniques like MIG or TIG welding, resistance spot welding excels in speed and safety. With resistance spot welding, localized heating occurs at the joint, allowing for quick welds without spreading heat throughout the entire workpiece, which can often distort materials or necessitate extensive cooling time.

One of the key advantages of resistance spot welding is its minimal preparation and clean-up. Unlike other methods that may require grinding or extensive surface preparation to achieve a good weld, resistance spot welding can be done with little to no additional work. This not only saves time but also reduces the cost associated with materials and labor.

Tips: When considering resistance spot welding for your projects, ensure that your materials are compatible and clean. Proper alignment of the pieces will enhance the performance of the welder and the quality of the weld. Additionally, training on machine operation can significantly improve outcomes, ensuring you make the most of this efficient welding method.

Why Choose a Resistance Spot Welder for Your Welding Projects

| Welding Technique | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Resistance Spot Welding | Fast process, minimal heat affected zone, good for thin materials. | Limited to lap joints, requires access to both sides of the material. | Automotive industry, sheet metal assemblies, electronics. |

| MIG Welding | Versatile for different materials, deep penetration, high speed. | Higher heat input can warp materials, requires shielding gas. | Construction, automotive repair, fabrication. |

| TIG Welding | High precision, clean finishes, can weld a wide range of metals. | Slower process, requires more skill, can be costly. | Aerospace, art, high-end fabrication. |

| Stick Welding | Good for outdoor work, portable, low cost. | Limited to thicker materials, generates significant spatter. | Heavy industry, repair work, construction. |

Maintenance Tips for Optimal Performance of Spot Welders

Maintaining a resistance spot welder is crucial for ensuring its optimal performance and longevity. Regular maintenance not only improves the efficiency of the machine but also enhances the quality of the welds produced. According to industry reports, proper maintenance can increase the lifespan of a welder by up to 50%. This involves routine checks on components such as the electrodes, power supply, and cooling systems. For example, keeping the electrodes clean and properly aligned is essential, as dirty or misaligned electrodes can lead to inconsistent welds and increased wear.

Another important aspect of maintenance is monitoring the electrical connections and calibration settings. A report from the American Welding Society highlights that precisely calibrated machines produce welds with fewer defects, thereby reducing material waste by nearly 20%. Additionally, operators should conduct regular inspections for any signs of wear and tear, as early detection can save significantly on repair costs and downtime. Implementing a schedule for these maintenance tasks, ideally every few weeks depending on usage frequency, ensures that the resistance spot welder remains in peak operating condition. By prioritizing these maintenance tips, welders can achieve optimal performance and high-quality outcomes in their welding projects.

Related Posts

-

2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

-

Ultimate Guide to Buy Mig Welder Tips for Beginners and Experts

-

10 Essential Tips for Welding Metal Like a Pro: Techniques and Safety

-

2025's Ultimate Guide to the Top 10 Portable Spot Welders for Every DIYer

-

Understanding What a Spot Welding Machine Is and Its Applications

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request